In the relentless pursuit of efficiency, quality, and competitiveness, modern manufacturing has undergone a profound transformation. Gone are the days of manual tracking, fragmented data, and reactive decision-making. Today, the beating heart of a productive factory lies in its digital infrastructure, and at the core of this infrastructure is Shop Floor Software. More than just a tool, it is the nervous system that connects planning to execution, transforming raw data into actionable insights and empowering manufacturers to achieve unprecedented levels of operational excellence.

This comprehensive guide will delve into what shop floor software is, explore its key components, illuminate the myriad benefits it offers, address the challenges of its implementation, and cast a gaze into its exciting future.

What Exactly is Shop Floor Software?

Shop floor software refers to a suite of digital applications and systems designed to manage, monitor, and optimize manufacturing operations directly on the factory floor. It acts as the bridge between the enterprise-level planning systems (like ERP – Enterprise Resource Planning) and the actual physical production processes. Its primary goal is to provide real-time visibility, control, and data collection from machines, operators, and materials, thereby enabling more agile, informed, and efficient production.

Often, shop floor software is synonymous with or a critical component of a Manufacturing Execution System (MES). While MES is a broader term encompassing the entire execution layer, shop floor software can also refer to more specialized applications focusing on specific aspects like quality control, maintenance, or data acquisition. Regardless of the exact terminology, its essence remains the same: bringing intelligence and automation to the point of production.

Key Components and Functionalities

Shop floor software isn’t a monolithic entity; rather, it’s a collection of integrated modules, each addressing a specific facet of manufacturing operations. The most common and critical components include:

-

Production Monitoring & Data Collection:

- Real-time Data Acquisition: Automatically collects data from machines (PLCs, SCADA systems, sensors), operators (manual input, barcode scanning), and processes. This includes machine status (running, idle, stopped), cycle times, production counts, and error codes.

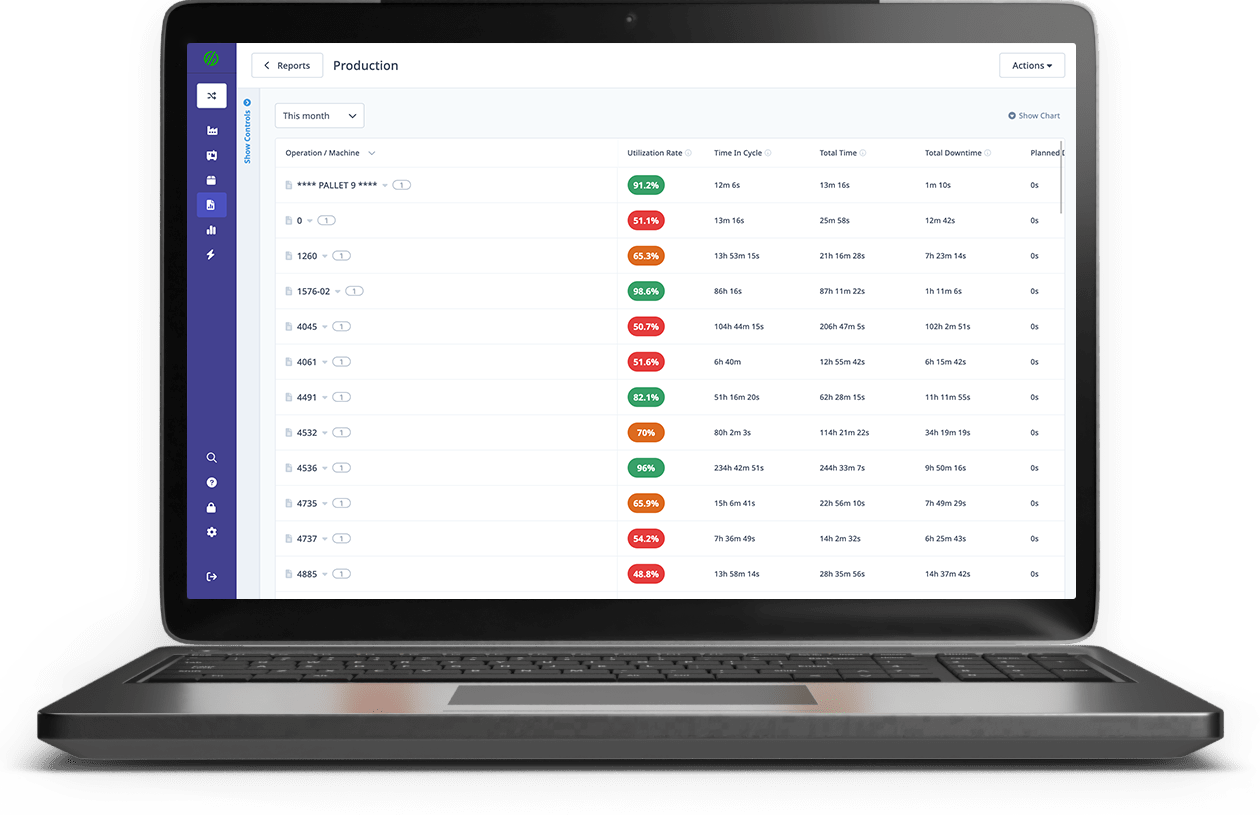

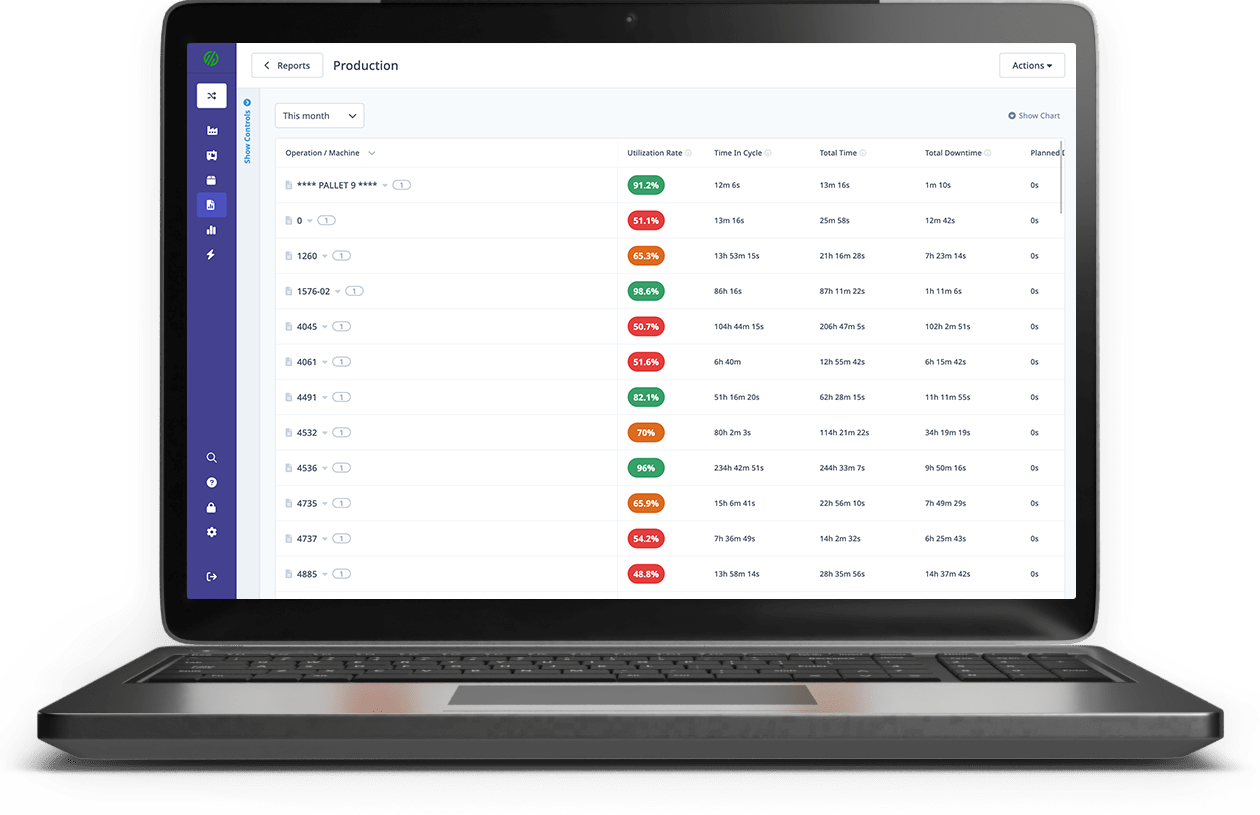

- Overall Equipment Effectiveness (OEE): Calculates and displays OEE metrics (Availability, Performance, Quality) in real-time, providing a holistic view of equipment efficiency and identifying bottlenecks.

- Dashboards & Visualizations: Presents complex data in easily understandable graphical dashboards, often displayed on large screens on the shop floor, allowing operators and supervisors to quickly grasp current performance.

-

Work Order Management & Scheduling:

- Digital Work Orders: Replaces paper-based work orders with digital versions, providing clear instructions, bill of materials (BOM), routings, and specifications directly to operators.

- Dynamic Scheduling: Adjusts production schedules in real-time based on machine availability, material shortages, and unexpected events, optimizing flow and minimizing delays.

- Dispatching & Sequencing: Guides operators on which tasks to perform next, ensuring efficient resource allocation and adherence to production plans.

-

Quality Management:

- Statistical Process Control (SPC): Monitors production processes to detect variations and ensure products remain within quality specifications, often with real-time alerts.

- Non-Conformance Management: Records, tracks, and manages defects, deviations, and rework processes, facilitating root cause analysis and continuous improvement.

- Traceability: Captures comprehensive data about materials, processes, operators, and equipment used for each product, enabling full backward and forward traceability for quality audits and recall management.

-

Maintenance Management:

- Computerized Maintenance Management Systems (CMMS) Integration: Often integrates with or includes modules for tracking machine health, scheduling preventive maintenance, managing spare parts, and logging repairs.

- Predictive Maintenance: Utilizes data from sensors and machine learning to predict potential equipment failures before they occur, minimizing unplanned downtime.

-

Inventory & Material Tracking:

- Real-time Material Flow: Tracks raw materials, work-in-progress (WIP), and finished goods as they move through the production process.

- Material Lot & Serial Number Tracking: Ensures precise inventory control and traceability of specific material batches.

- Automated Replenishment: Triggers alerts or replenishment orders when material levels fall below predefined thresholds.

-

Labor Tracking & Management:

- Operator Performance Tracking: Monitors operator efficiency, time spent on tasks, and skill utilization.

- Time & Attendance: Manages employee clock-in/out and breaks directly on the shop floor.

- Skill Matrix: Matches operators with the necessary skills to specific tasks, ensuring compliance and optimal resource allocation.

-

Reporting & Analytics:

- Customizable Reports: Generates detailed reports on production output, downtime, quality metrics, labor efficiency, and more.

- Advanced Analytics: Leverages historical data to identify trends, predict future performance, and support strategic decision-making.

The Unifying Power: Bridging the Gaps

Crucially, shop floor software doesn’t operate in isolation. It integrates seamlessly with other enterprise systems:

- ERP (Enterprise Resource Planning): Receives production orders and BOMs from ERP and sends back real-time production updates, inventory consumption, and quality data.

- PLM (Product Lifecycle Management): Accesses up-to-date product designs and specifications.

- SCADA/PLC Systems: Communicates directly with machine controllers for data acquisition and process control.

This integration eliminates data silos, ensures data consistency across the organization, and provides a unified, accurate view of manufacturing operations from the top floor to the shop floor.

Benefits of Implementing Shop Floor Software

The strategic implementation of shop floor software delivers a multitude of tangible and intangible benefits, revolutionizing manufacturing operations:

-

Enhanced Visibility & Real-time Insights:

- Provides an immediate, accurate picture of production status, machine performance, and potential issues.

- Empowers supervisors and managers to make proactive, data-driven decisions rather than reactive ones.

-

Increased Efficiency & Productivity:

- Identifies bottlenecks, idle time, and process inefficiencies, allowing for rapid corrective actions.

- Optimizes machine utilization and operator output, leading to higher throughput.

- Reduces manual data entry and associated errors, freeing up operators for value-added tasks.

-

Improved Quality & Compliance:

- Enforces quality checks and specifications at every stage, reducing defects and rework.

- Provides comprehensive traceability for regulatory compliance, customer audits, and efficient recall management.

- Facilitates faster root cause analysis for quality issues, leading to continuous improvement.

-

Reduced Costs & Waste:

- Minimizes scrap, rework, and material waste through better process control.

- Reduces inventory holding costs by optimizing material flow and replenishment.

- Decreases unplanned downtime through proactive maintenance and real-time alerts.

-

Better Decision-Making:

- Transforms raw data into actionable intelligence, enabling more strategic planning and operational adjustments.

- Supports continuous improvement initiatives by providing robust data for analysis and validation.

-

Enhanced Traceability and Accountability:

- Documents every step of the production process, from raw material to finished product, critical for industries like aerospace, medical devices, and food & beverage.

- Increases accountability among operators and teams through clear performance metrics.

-

Improved Workforce Management:

- Provides clear work instructions, reducing training time and operator errors.

- Helps allocate resources more effectively based on skills and availability.

Challenges and Considerations for Implementation

While the benefits are compelling, implementing shop floor software is not without its challenges:

- Integration Complexities: Integrating with existing legacy systems (ERP, SCADA, PLCs) can be complex and require significant IT effort.

- Cost & ROI Justification: The initial investment can be substantial, requiring a clear business case and demonstrable ROI to secure funding.

- Change Management & Training: Resistance from employees accustomed to traditional methods is common. Effective change management strategies and comprehensive training are crucial for adoption.

- Data Security: Protecting sensitive production data from cyber threats is paramount, requiring robust security protocols.

- Customization vs. Off-the-Shelf: Deciding between a highly customized solution and a more standardized, off-the-shelf package involves trade-offs between specific needs and implementation time/cost.

- Data Quality: The effectiveness of the software hinges on the quality and accuracy of the data fed into it. Poor data in equals poor insights out.

The Future of Shop Floor Software

The evolution of shop floor software is closely tied to advancements in Industry 4.0 technologies. The future promises even more intelligent, autonomous, and interconnected systems:

- Internet of Things (IoT) & Edge Computing: Increasingly, sensors and smart devices embedded in machines will feed vast amounts of data directly to edge computing devices for immediate processing, reducing latency and improving responsiveness.

- Artificial Intelligence (AI) & Machine Learning (ML): AI and ML algorithms will power predictive analytics (e.g., predicting machine failure, quality deviations), optimize scheduling in real-time, and even automate decision-making on the shop floor.

- Cloud-Based Solutions: Cloud platforms offer scalability, flexibility, and reduced infrastructure costs, making advanced shop floor capabilities accessible to a broader range of manufacturers, especially SMEs.

- Augmented Reality (AR) & Digital Twins: AR will assist operators with interactive work instructions, maintenance guidance, and real-time data overlays. Digital twins will create virtual replicas of the entire production process, enabling simulations, optimization, and predictive maintenance in a risk-free environment.

- Increased Human-Machine Collaboration: Future systems will be designed for more intuitive interaction, allowing humans and machines to work together seamlessly, enhancing safety and productivity.

Choosing the Right Solution

Selecting the right shop floor software requires a thorough understanding of an organization’s specific needs, processes, and long-term goals. Key considerations include: scalability, integration capabilities, vendor support, user-friendliness, and compliance with industry standards. A phased implementation approach, starting with critical modules and expanding gradually, can often mitigate risks and ensure a smoother transition.

Conclusion

Shop floor software is no longer a luxury but a necessity for manufacturers striving for operational excellence in today’s dynamic global landscape. By digitizing, automating, and integrating the core processes of the factory floor, it provides the real-time visibility and control essential for optimizing production, enhancing quality, reducing costs, and fostering continuous improvement. As Industry 4.0 technologies continue to mature, shop floor software will evolve further, ushering in an era of even smarter, more agile, and highly competitive manufacturing operations, truly unlocking the full potential of the modern factory.